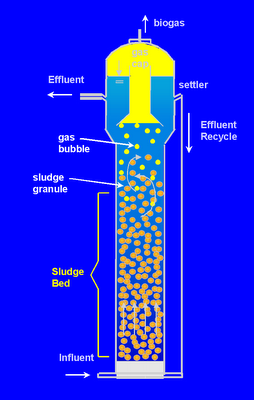

Expanded Granular Sludge Bed Digestion is a modification of the Up Flow Anaerobic Sludge Blanket Digestion approach. The advantage of the former is greater upward-flow velocity. The increased rate of wastewater passing through the sludge bed is either accomplished with tall reactors, or by incorporating an effluent recycle (or both). Both systems include the harvesting of bio-methane.

Emeka Okafor is hopeful that a low-cost, household septic tank system will make a difference. Cheick Amala Tabouré has designed a project in Mali (AREM - Association pour la Rehabilitation de l'Environnement) that not only carefully considers implementation of an improved, septic tank system, he has "created a loan fund to enable households to afford it" and a training program to instruct unemployed local youth on how to construct the tanks.

The plans call for the septic tank constructed in a pit four meters deep. The actual depth depends upon the water table, which Tabouré is striving to preserve. The bottom of the pit is covered with porous material and the pit is then lined and covered with concrete slabs.

Unquestionably, such innovation need go hand in hand with increased waste recycling. Wikipedia notes the following septic tank problems:

1. Excessive dumping of cooking oils and grease can fill up the upper portion of the septic tank and can cause the inlet drains to block. Oils and grease are often difficult to degrade and can cause odor problems and difficulties with the periodic emptying.

2. Flushing non-biodegradable hygiene products such as sanitary towels, cotton buds etc. will rapidly fill or clog a septic tank and these materials should not be disposed of in this way.

3. The use of waste macerators or grinders for disposal of waste food will cause a rapid overload of the system and early failure.

4. Certain chemicals may damage the working of a septic tank, especially pesticides, herbicides, materials with high concentrations of bleach or caustic soda (lye) or any other inorganic materials such as paints, solvents etc.

5. Roots from trees and shrubbery growing above the tank or the drain field may clog and or rupture them.

6. Playgrounds and storage buildings may cause damage to a tank and the drainage field. In addition, covering the drainage field with an impervious surface or hard-standing will seriously affect its efficiency.

Recycling can address the first four issues. For instance, instead of dumping grease or other animal rendering into the pit, the material is recycled into a fuel, e.g., bio-diesel. Municipal solid waste is incinerated; vegetable material is composted; and, chemicals collected for safe, industrial recycling.

Another opportunity for recycling is the use of constructed wetlands, which are beds of marsh reed cultivated for efficient small-scale, sewage treatment. Wastewater trickling through the reed bed is cleansed by the extensive root system of the reed bed. The entire ecosystem results in an extremely clean effluent.

In terms of low cost construction, one might imagine an opportunity to introduce, an innovative material that goes by various names depending upon where and who is making it. You could call it: Autoclaved Concrete, Aerated Autoclaved Concrete, Autoclaved Aerated Concrete, Cellular Concrete, Porous concrete or Aircrete. Take your pick. No matter what name it goes by, such precast slabs of concrete are easier to handle because they are porous and weigh significantly less.

And, new products are on the horizon that could reduce cost of aerated concrete. Developed in Australia, HySSIL is a patented, high strength, lightweight concrete building product with a cost comparable to conventional concrete.

The costs of establishing a HySSIL manufacturing plant are inexpensive due to the small scale practical for the economic production of HySSIL and are comparable with a conventional precast concrete plant. The costs are less than one tenth of the costs of establishing competitive production plants such as an autoclaved aerated concrete plant, due to the elimination of the autoclaving process.

Another, subsequent opportunity for innovation would be the design of a low cost, effective system for processing bio-solids. One standard approach for emptying septic and conservancy tanks is to employ a tanker truck equipped with a sludge pump. Such trucks are expensive and difficult to introduce into the narrow alleys of many third world slums.

Then the question is: "What to do with the sludge?" Integration of biosolids management into urban agriculture requires knowledge of soil science. Use of bio-solids in agriculture must be done in a healthy, environmentally sound manner.

There is critical problem of human waste disposal in urban areas of developing countries. The Timbuktu Chronicles article provides several references:

- The Unglamorous Solution for Saving Lives and Improving Human Development

- Pits designed by the Kigali Institute of Science and Technology

- Shit Business is Serious Business

- Barrel Type Composting of Municipal Solid Waste

Labels: composting, design, development, environment, health, innovation, manufacturing, microfinance, sanitation

More info here

http;//www.mtmdrains.co.uk

Correction to link:

http://www.mtmdrains.co.uk/